Overview of Pipe Fittings in Oil and Gas Operations

Pipe fittings are components used to connect, control, change direction, or terminate the flow of fluids in piping systems. In oil and gas applications, these fittings must meet strict industry standards such as ASME, ASTM, and API to withstand high pressures, temperatures, and corrosive environments.

There are several types of pipe fittings used in the oil and gas sector, including:

Elbows (to change direction)

Tees (to branch flow)

Reducers (to change pipe diameter)

Couplings and Unions (to connect or disconnect pipe segments)

Caps and Plugs (to seal pipe ends)

Flanges (for bolted connections)

Crosses and Swages (for specialized flow transitions)

Each type of fitting must be selected based on factors such as pressure rating, temperature, fluid type, and location (onshore vs. offshore).

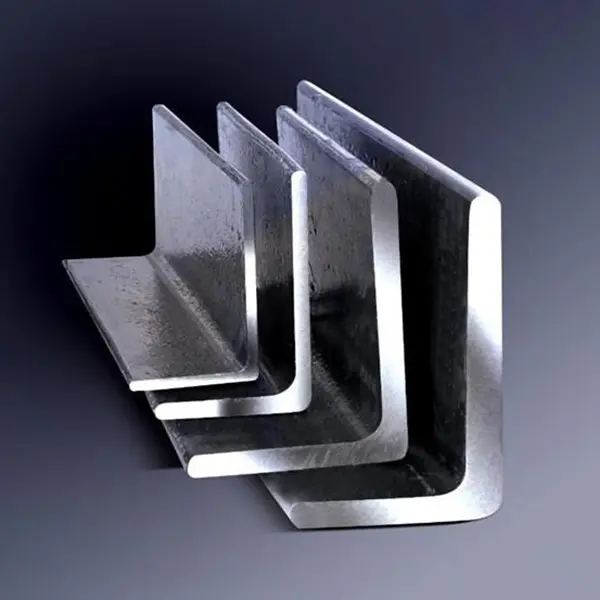

Importance of Carbon Steel Pipe Fitting

Carbon steel pipe fitting is the preferred choice in many oil and gas applications due to its excellent mechanical properties, including high tensile strength, impact resistance, and the ability to withstand high-pressure environments. It is also cost-effective compared to stainless steel or alloy materials.

Carbon steel fittings are typically manufactured from grades such as ASTM A234 WPB, which is designed for moderate and high-temperature service. These fittings are commonly used in both upstream (exploration and production) and downstream (refining and distribution) segments.

Advantages of carbon steel pipe fittings include:

Durability in harsh environments

Good weldability and machinability

Compatibility with most carbon steel pipelines

High pressure and temperature tolerance

Cost efficiency for large-scale installations

In environments where corrosion is a major concern—such as offshore rigs or sour gas fields—carbon steel fittings are often coated or combined with linings or inhibitors to improve corrosion resistance.

Upstream Applications

In the upstream segment, which involves the exploration and extraction of crude oil and natural gas, pipe fittings are used in wellheads, manifolds, gathering systems, and separation units. This stage involves extremely high-pressure and high-temperature conditions, requiring fittings that can perform reliably under stress.

Carbon steel pipe fittings are often used in:

Drilling operations: for high-pressure mud and fluid circulation systems

Wellhead assemblies: to direct flow from oil/gas wells

Manifolds and Christmas trees: for controlling and distributing the well stream

Since upstream infrastructure may be located in remote or offshore environments, fittings must be highly durable and easy to install and maintain.

Midstream Applications

The midstream segment is focused on the transportation and storage of oil and gas. It includes pipelines, pumping stations, and storage terminals. Carbon steel pipe fittings are essential in constructing and maintaining these long-distance pipeline systems.

In this segment, pipe fittings are used for:

Direction changes (via elbows and bends)

Pipeline branching (using tees and crosses)

Diameter adjustments (reducers)

Connection and isolation (flanges, unions, and valves)

Carbon steel pipe fittings are ideal for high-pressure transmission pipelines because they offer the required structural strength while being economically viable for extensive infrastructure projects.

Downstream Applications

The downstream sector covers the refining of crude oil, processing of natural gas, and distribution of finished products such as fuels, lubricants, and petrochemicals. This segment requires a vast network of pipelines and fittings for both process and utility services.

In oil refineries and chemical plants, carbon steel pipe fittings are used in:

Process piping: handling high-temperature fluids such as steam, hydrocarbons, and chemicals

Utility piping: for water, air, and cooling systems

Transfer lines: between distillation units, reactors, and storage tanks

Although some specialized systems may require stainless steel or alloy fittings for enhanced corrosion resistance, carbon steel remains dominant for general-purpose pipelines due to its versatility and affordability.

Standards and Quality Requirements

To ensure safety and performance, carbon steel pipe fittings in the oil and gas industry must comply with stringent standards, including:

ASME B16.9 (for factory-made wrought fittings)

ASME B16.11 (for forged fittings)

API 5L/5CT (for line pipe and casing standards)

NACE MR0175/ISO 15156 (for sour service applications)

Quality control measures such as hydrostatic testing, radiographic inspection, and material traceability are essential parts of the production and installation process.

Future Trends and Innovations

As the oil and gas industry evolves with new technologies such as enhanced oil recovery (EOR), subsea production systems, and digital pipeline monitoring, the demand for high-performance pipe fittings is increasing. There is growing interest in:

Advanced coatings and linings for corrosion control

Smart fittings equipped with sensors

High-strength low-alloy (HSLA) carbon steel for critical service

Additionally, modular construction and prefabrication techniques are becoming more common, requiring precision-engineered fittings that can be rapidly deployed.

Pipe fittings are indispensable in every phase of the oil and gas industry—from drilling wells in remote fields to refining fuel in complex petrochemical plants. Among the various types available, the carbon steel pipe fitting stands out for its strength, affordability, and adaptability to diverse environments. As global energy needs grow and industry standards tighten, carbon steel fittings will continue to play a vital role in ensuring the efficiency, safety, and reliability of oil and gas infrastructure.

Warning: Undefined array key "array_images_sha2r_all" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1419/footer.php on line 117

Warning: foreach() argument must be of type array|object, null given in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1419/footer.php on line 117